UK Leads the Charge in Space Robotics with Innovative Welding Technology

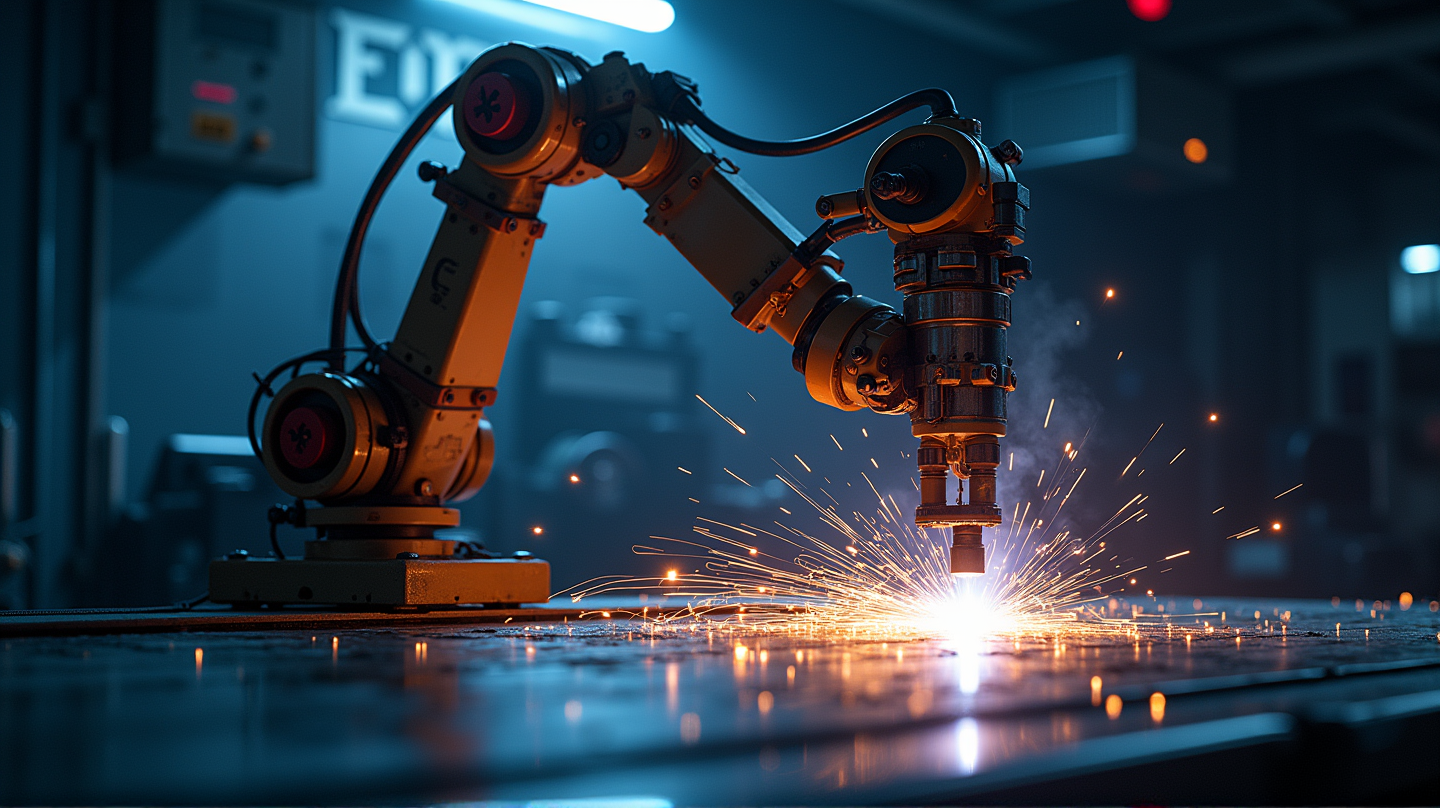

The UK is pioneering space robotic welding technology set to revolutionize satellite maintenance and orbital infrastructure.

The Dawn of ISPARK: Bridging Space Manufacturing Gaps

The University of Leicester, together with welding expert TWI Ltd, is spearheading a groundbreaking project—Intelligent SPace Arc-welding Robotic Kit (ISPARK). Awarded £560,000, including £485,000 from the UK Space Agency’s National Space Innovation Programme, the initiative seeks to pioneer the UK’s first robotic welding capabilities in the cosmos. This effort promises to redefine satellite repairs and manufacturing beyond Earth’s boundaries.

Conquering Space’s Intensive Challenges

Currently, space endeavors rely heavily on components enduring the harsh journey from Earth. Space welding introduces a transformative approach; however, it faces intense obstacles like vacuums, microgravity, and thermal extremes. These conditions make in-orbit repairs a rarity. Enter ISPARK: a beacon of change with its space-qualified robotic welding prowess.

Embracing Digital-Twin Modeling for Space Success

Dr. Daniel Zhou Hao from the University of Leicester elaborates on the project’s scope, highlighting the collaboration’s potential by blending AI robotics with top-tier welding knowledge. By employing digital-twin modeling, the research team can rigorously simulate space conditions on Earth, honing robust technology ready for the unforgiving cosmic landscape.

A New Era of Space Economy and Responsibility

Professor Dirk Schaefer suggests that mastering in-space welding will usher in a sustainable space economy. Such innovations are pivotal not just for extending mission lifetimes but also for enabling complex orbital constructs—from new-age telescopes to oncoming space stations. This movement proposes a roadmap towards reducing high mission costs and fostering responsible actions in space endeavors.

Global Pursuits Towards Space-Based Welding

Across the globe, scientific endeavors echo the UK’s ambitions. In the U.S., ThinkOrbital demonstrates autonomous in-space welding brilliance. Meanwhile, the University of Texas explores virtual environments replicating lunar surface conditions. Multi-method welding trials promise a future where space operations evolve into enduring economic systems.

Transforming Isolation Into Connectivity

As stated in Interesting Engineering, if these revolutionary projects succeed, they will morph space operations into long-term exploratory expansions, moving away from isolated, costly missions towards interconnected, self-sustaining systems. This heralds a new dawn for space exploration—one in which remote welding not only repairs and maintains but also constructs the future.